Henke Industrial

Leading Seamless Transitions

Turnkey equipment relocation, rigging, and millwright services engineered for safety, uptime, and precision across North America and worldwide.

Henke Industrial provides turnkey equipment relocation, rigging and millwright services for manufacturers across North America and worldwide. Our OSHA 30-certified crews plan, lift, transport, and reinstall heavy machinery with engineered precision to minimize downtime, protect uptime, and keep production running safely.

Why Manufacturers Trust Henke

Safety First - OSHA-30 Certified Crews

Engineered Lift Plans for Every Move

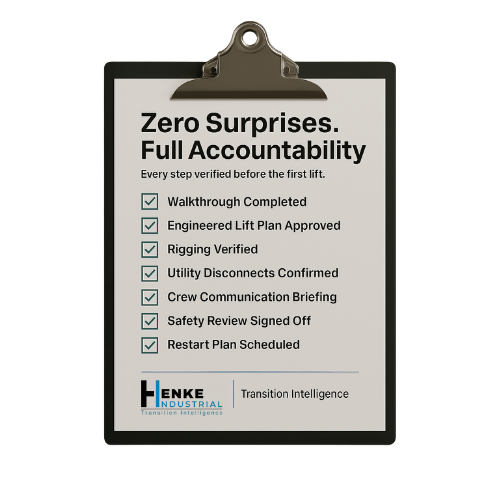

Zero Surprises, Full Accountability

Uptime Protection - Downtime costs average $16,000/hr (Learn how we prevent costly delays)

Our Services

-

Industrial Plant Relocation & Turnkey Services

Henke Industrial provides complete plant relocation, facility transfer, and turnkey equipment move management for manufacturers across North America. Our team plans, dismantles, transports, reinstalls, and recommissions entire production systems with engineered precision, ensuring a controlled, downtime-minimized transition from start to restart.

-

Rigging & Millwright Services

We deliver precision rigging, machinery moving, and equipment installation services for heavy industrial assets and structural components. Every lift follows an engineered lift plan and verified load path to ensure safe, efficient handling and accurate machine alignment at the destination.

-

Technical Services & PLC Programming

Henke Industrial provides automation, controls integration, and PLC programming services to keep relocated or upgraded equipment performing to spec. Our technical specialists handle commissioning, calibration, and troubleshooting to ensure seamless system restart and process reliability.

-

Heavy Hauling & Logistics

Our team manages heavy equipment transport, machinery hauling, and specialized logistics coordination for large-scale relocation projects. We conduct route surveys, secure DOT permitting, and oversee loading and unloading to protect assets during every mile of transit.

-

Cleaning & Maintenance Services

Henke Industrial provides industrial cleaning, facility restoration, and preventive maintenance services that support safe transitions during relocations or shutdowns. Our crews handle degreasing, pit filling, floor repair, and equipment maintenance to prepare and restore facilities efficiently.

-

Facility Services

We manage site readiness, utility coordination, and facility modification services that keep relocation projects on schedule and in compliance. Henke’s OSHA 30-certified teams handle electrical, compressed air, gas, and water disconnects, slab repair, anchoring, and restart sequencing.

-

Additional Services

Henke Industrial offers fabrication, inspection, crating, and asset management services that support every stage of your project. From non-destructive testing and export packaging to long-term machinery storage, we provide the additional expertise that keeps complex moves organized and verified.

Industries We Serve

-

Aerospace & Defense

We relocate precision aerospace machinery, tooling, and production systems under strict compliance and safety standards.

-

Automotive

Henke manages full line transfers, robotics integration, and OEM changeovers with engineered sequencing and verified system startup.

-

Process Manufacturing

We handle equipment relocation, process line transfers, and production restarts for continuous and batch manufacturing environments.

-

Industrial Products

Henke Industrial moves and reconfigures production lines, presses, and assembly equipment to keep operations efficient and compliant.

-

Metals & Fabrication

We perform heavy equipment moves, press line installations, and structural rigging for fabrication, machining, and forming operations.

-

OEMs

Our team supports factory acceptance testing, equipment delivery, and on-site installation for original equipment manufacturers worldwide.

-

Packaging & Logistics

Henke executes conveyor line relocation, automation integration, and dock-to-line material handling projects for packaging facilities.

-

Plastics & Composites

We manage machine relocation, temperature-controlled equipment moves, and utility coordination for plastics and composite production operations.

Why Choose Henke?

-

OSHA 30-Certified Crews with Decades of Experience

Every member of our field team holds OSHA 30 certification and brings decades of hands-on experience working with complex industrial equipment. That depth of training and familiarity means every lift, move, and installation is executed safely, efficiently, and to exact standards.

-

Engineered Lift Plans Prevent Costly Surprises

We design every lift around the specific weight, geometry, and structural limits of your facility. Engineered lift plans eliminate guesswork, reduce on-site risk, and prevent the unexpected issues that lead to damage, delays, or extended downtime.

-

Clients Have Cut Downtime by as Much as 40%

Our detailed sequencing, parallel site prep, and off-hour execution strategies help manufacturers restart faster. By planning every phase around your production goals, Henke has helped clients reduce downtime by as much as 40% on complex relocations.

-

Henke Industrial provides turnkey equipment relocation, rigging, and millwright services for manufacturers across North America and worldwide. Our team manages every phase from disassembly to reinstallation with engineered precision and verified safety compliance.

-

Every project is planned around the client’s production schedule using engineered lift plans, parallel site preparation, and off-hour execution. This approach helps reduce rework, prevent delays, and shorten restart times.

-

Each Henke field team member holds OSHA 30 certification and follows documented rigging, lift, and confined-space procedures. Every project includes hazard assessments, pre-lift verification, and full safety documentation before work begins.

-

Yes. Henke coordinates electrical, air, gas, and water disconnects and reconnections, along with floor and pit repairs, anchoring, and restart readiness to ensure a smooth transition between facilities.

Frequently Asked Questions

*Don’t see your question here?

If your question isn’t listed, our team can connect you with a project specialist who will review your specific equipment, timeline, and site requirements.

Visit our full FAQ page for more answers, or contact our team at (859) 757-8080 to start the conversation.

Have a Question?

Submit a Question.

We’ll be glad to clarify or walk your floor.

-

We handle a wide range of industrial machinery, from robotics and automated lines to large presses, conveyors, and process systems. Each move is engineered for balance, clearance, and alignment to ensure safe, accurate installation.

-

Yes. We coordinate electrical, air, gas, and water disconnections and reconnections, along with floor and pit repairs, anchoring, and site cleanup. Our goal is to have your facility fully ready for restart without delay.

-

Yes. Henke Industrial carries $6 million in liability coverage, well above industry minimums, as part of our commitment to protecting client assets and ensuring total project confidence.

-

Project timing depends on scope and site readiness, but our team can mobilize quickly once planning and safety reviews are complete. Early engagement helps us identify risks, coordinate utilities, and secure the equipment needed to keep your schedule on track.

Examples of Our Work

See how Henke Industrial executes complex relocations with engineered control and zero downtime.

Robotic Line Relocation

Want to see how proper planning prevents costly downtime?

Read our [Equipment Relocation Planning Guide]

Heavy Machinery Removal